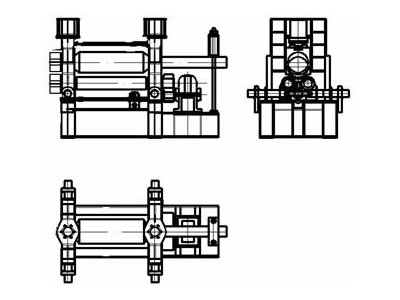

Vertical Plate Rolling Machine

Description

The vertical rolling machine is a general device used for rolling thin plates and large diameter workpieces. The main merit is that vertical plate bending machine or vertical bending machine possesses simple structure, reliable operation and easy maintenance. The two side pillars can do parallel movement along the machine's centerline. The distance between the two pillars can be adjustable. When operators use vertical plate bending machine to bend rolls, they should put the steel plate between roller and pillar. The vertical rolling machine's pinch roller uses hydraulic pressure to press the steel plate against the roller. The two side pillars put forward towards the roller direction to make local bending of the steel plate. Then the pillar will return to its original position. The drive roll of this plate bending machine makes the steel plate move a certain distance. The side pillars will put forward again to bend the steel plate. With this repetitive movement, this vertical rolling machine will bend steel plate into circular shape plate.

The vertical rolling machine is a general device used for rolling thin plates and large diameter workpieces. The main merit is that vertical plate bending machine or vertical bending machine possesses simple structure, reliable operation and easy maintenance. The two side pillars can do parallel movement along the machine's centerline. The distance between the two pillars can be adjustable. When operators use vertical plate bending machine to bend rolls, they should put the steel plate between roller and pillar. The vertical rolling machine's pinch roller uses hydraulic pressure to press the steel plate against the roller. The two side pillars put forward towards the roller direction to make local bending of the steel plate. Then the pillar will return to its original position. The drive roll of this plate bending machine makes the steel plate move a certain distance. The side pillars will put forward again to bend the steel plate. With this repetitive movement, this vertical rolling machine will bend steel plate into circular shape plate.

Advantages

- Different from horizontal bending machine, vertical plate bending machine bends steel plates into tube sections intermittently instead of continuously.

- HB vertical rolling machine has strong bending capability that it can bend steel plates into different shapes once.

- Vertical bending machine covers small surface area. It can avoid indentation.

Technical Parameters of Vertical Plate Rolling Machine

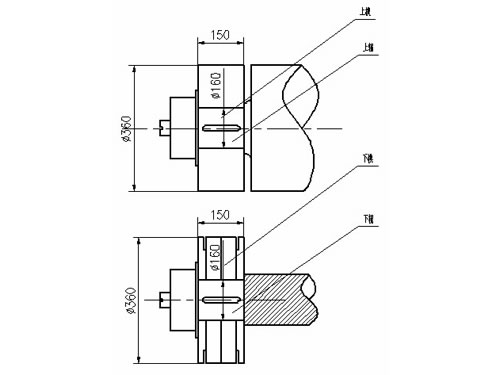

| Model | Max. Thickness (mm) | Max. Width (mm) | Coiling Speed (m/min) | Loaded Minimum Diameter (mm) | Front Roll Diameter (mm) | Back Roll Diameter (mm) | Main Motor Power (kw) |

| W11T-20×800 | 20 | 800 | 4 | 650 | 260 | 240 | 15 |

| W11T-10×3000 | 25 | 3000 | 4 | 500 | 330 | 270 | 30 |

George Wang

Regards,

Sino Machinery Manufacture And Construction Engineering Co.,Ltd.

The exhibition we will attend recently:

1. 2013 The 2nd China International Steel Silo Technology Equipment Exhibition 18~20th Jun, Shanghai Wold Expo Exhibition & Convention Center

2. 2013 The 114th China Export Commodities Fair (Canton Fair) 15~19th Oct, Guangzhou Pazhou Complex

3. 2013 The 10th China Fair Jordan 16~19th Sep, Amman International Exhibition Center, Jordan

4. 2013 Big5 Building Machine Exhibition 25~28th Nov, Dubai International Exhibition & Conference Center

English: www.kspanmachinery.com

Spanish: www.kspanmachine.es

French: www.kspanmachine.fr

Russian: www.kspanmachine.ru

Portuguese: www.kspanmachine.pt

Sounth Africa: www.kspanmachine.co.za

-----------------------------------------------------------------------

SINO GROUP

TEL: 0086-18831115581, 15027709266

FAX: 0086-31186059205, 13131196091

SINO group is big stated owned corporation and has specialized in machinery and construction industry over 30 years. As one of the most famous manufacturers in China, we have committed ourselves to develop and produce various ways of new building materials and methods.

SINO group is professional construction materials supplier, machinery manufacturer and construction contractor for LARGE SPAN BUILDING SYSTEM, SIP BUILDING SYSTEM, ICF BUILDING SYSTEM, SHEARING AND SLITTING, CURVING AND BENDING, and all kinds of MATERIAL PRODUCTION LINE in China and we offer all kinds of service in the field of construction building with favourable price and high quality to you.